What are Industrial Chiller Systems?

Commercial buildings use Heating, Ventilation and Air Conditioning (HVAC) systems to dehumidify and to cool the building. Modern commercial buildings seek efficient HVAC systems and components as part of broader initiatives centered on building performance and sustainability. Building occupants similarly carry great expectations, that the HVAC system will function as intended . . . to create a comfortable interior environment regardless of the conditions external to the building.

Chillers have become an essential HVAC component of a wide variety of commercial facilities, including hotels, restaurants, hospitals, sporting arenas, industrial and manufacturing plants, etc. The industry has long recognized that chiller systems represent the single largest consumer of electrical usage in most facilities. They can easily consume more than 50% of the total electrical usage during seasonal periods. According to the US Department of Energy (DOE), chillers can combine to use approximately 20% of the total electric power generated in North America. Moreover, the DOE estimates that chillers can expend up to 30% in additional energy usage due to various operational inefficiencies. These acknowledged inefficiencies cost companies and building facilities billions of dollars annually.

In general, a chiller facilitates the transfer of heat from an internal environment to an external environment. This heat-transfer device relies on the physical state of a refrigerant as it circulates through the chiller system. Certainly, chillers can function as the heart of any central HVAC system.

How Does a Chiller Work?

A chiller works on the principle of vapor-compression or vapor absorption. Chillers provide a continuous flow of coolant to the cold side of a process water system at a desired temperature of about 50°F (10°C). The coolant is then pumped through the process, extracting heat out of one area of a facility (e.g., machinery, process equipment, etc.) as it flows back to the return side of the process water system.

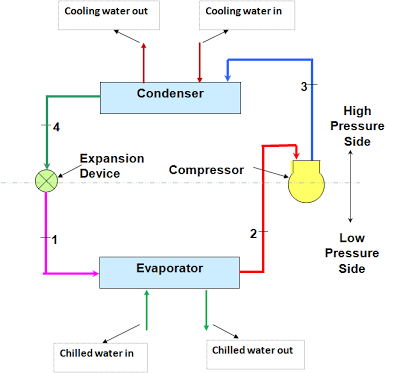

A chiller uses a vapor compression mechanical refrigeration system that connects to the process water system through a device called an evaporator. Refrigerant circulates through an evaporator, compressor, condenser and expansion device of a chiller. A thermodynamic process occurs in each of above components of a chiller. The evaporator functions as a heat exchanger such that heat captured by the process coolant flow transfers to the refrigerant. As the heat transfer takes place, the refrigerant evaporates, changing from a low-pressure liquid into vapor, while the temperature of the process coolant reduces.

The refrigerant then flows to a compressor, which performs multiple functions. First, it removes refrigerant from the evaporator and ensures that the pressure in the evaporator remains low enough to absorb heat at the correct rate. Second, it raises the pressure in outgoing refrigerant vapor to ensure that its temperature remains high enough to release heat when it reaches the condenser. The refrigerant returns to a liquid state at the condenser. The latent heat given up as the refrigerant changes from vapor to liquid is carried away from the environment by a cooling medium (air or water).

Types of Chillers:

As described, two different cooling mediums (air or water) can facilitate the transfer of the latent heat given up as the refrigerant changes from vapor to liquid. Thus, chillers can use two different types of condensers, air-cooled and water-cooled.

- Air-cooled condensers resemble the “radiators” that cool automobile engines. They use a motorized blower to force air across a grid of refrigerant lines. Unless they are specially designed for high-ambient conditions, air-cooled condensers require ambient temperatures of 95°F (35°C) or below to operate effectively.

- Water-cooled condensers perform the same function as air-cooled condensers, but require two steps to complete the heat transfer. First, heat moves from refrigerant vapor into the condenser water. Then, the warm condenser water is pumped to a cooling tower where the process heat is ultimately discharged to the atmosphere.

Water-Cooled Chillers:

Water-cooled chillers feature a water-cooled condenser connected with a cooling tower. They have commonly been used for medium and large installations that have a sufficient water supply. Water-cooled chillers can produce a more constant performance for commercial and industrial air conditioning because of the relative independence to fluctuations of the ambient temperature. Water-cooled chillers range in size from small 20-ton capacity models to several thousand-ton models that cool the world’s largest facilities such as airports, shopping malls and other facilities.

A typical water-cooled chiller uses recirculating condenser water from a cooling tower to condense the refrigerant. A water-cooled chiller contains a refrigerant dependent on the entering condenser water temperature (and flow rate), which functions in relation to the ambient wet-bulb temperature. Since the wet-bulb temperature is always lower than the dry-bulb temperature, the refrigerant condensing temperature (and pressure) in a water-cooled chiller can often operate significantly lower than an air-cooled chiller. Thus, water-cooled chillers can operate more efficiently.

Water-cooled chillers typically reside indoors in an environment protected from the elements. Hence, water-cooled chiller can offer a longer lifespan. Water-cooled chillers typically represent the only option for larger installations. The additional cooling tower system will require additional installation expense and maintenance as compared to air-cooled chillers.

Air-Cooled Chillers:

Air-cooled chillers rely on a condenser cooled by the environment air. Thus, air-cooled chillers may find common application in smaller or medium installations where space constraints may exist. An air-cooled chiller can represent the most practical choice in scenarios where water represents a scarce resource.

A typical air-cooled chiller can feature propeller fans or mechanical refrigeration cycles to draw ambient air over a finned coil to condense the refrigerant. The condensation of the refrigerant vapor in the air-cooled condenser enables the transfer of heat to the atmosphere.

Air-cooled chillers offer the significant advantage of lower installation costs. Simpler maintenance also results due to their relative simplicity as compared to water-cooled chillers. Air-cooled chillers will occupy less space, but will mostly reside outside a facility. Thus, the outdoor elements will compromise their functional lifespan.

The all-inclusive nature of air-cooled chillers reduces maintenance costs. Their relative simplicity coupled with reduced space requirements produces great advantages in many types of installations.

Actions to Increase Efficiency of Chiller Systems:

Chiller costs consume a substantial part of your building’s utility bills. What measures should one take to obtain energy savings through maximal efficiency of the chiller system? Let’s examine some possibilities.

Ongoing Maintenance

Chiller systems will operate more efficiently through proper ongoing maintenance. Most organizations recognize this value and have taken steps as part of their day-to-day facility management best practices. Some common best practices for chiller systems include:

Inspect and clean condenser coils. Heat transfer has a large effect on chiller systems and remains fundamental to producing efficient chiller operations. Routine maintenance should inspect condenser coils for clogging and free air passage.

Maintain refrigerant charge. A chiller’s cooling quotient depends on proper refrigerant levels in the system. Maintaining proper refrigerant charge can greatly impact energy efficiency by reducing cooling costs by nearly 5-10%.

Maintain condenser water: Condenser water loops used with cooling towers must maintain proper water flow as designed. Any debris like sand, erosive solids, and contamination materials can affect the condenser water loop. Fouling or scaling can inhibit water flow and greatly impact the chiller’s operating efficiency.

Predictive Maintenance

Artificial Intelligence (AI) continues to advance in everyday practical applications. Machinery such as chiller systems will benefit from AI algorithms that can detect potential failures before they occur. Predictive maintenance leverages the collection and analysis of chiller system operational data to determine when maintenance actions should be taken prior to catastrophic failure. As chillers systems represent the heart of most modern HVAC systems, the prevention of catastrophic failures that produce significant “downtime” will save on emergency repair costs as well as reputation. The critical role played by a chiller system warrants the increased scrutiny. Big Data and AI will minimize downtime and maximize productivity.

The Internet of Things (IoT) provides the data collection tool that can enable AI applications such as predictive maintenance. In fact, the future of HVAC is AI and IoT. IoT enables the collection of real-time data from a chiller to enable a continual analysis of its operation. The granular IoT data collected from a chiller will go far beyond that obtained by visual inspection. IoT connects building engineers to real-time visibility of critical HVAC assets, thereby enabling informed monitoring of actual operating conditions.

Optimization

Chillers operate as part of a complex HVAC system. Water-cooled chillers have greater complexity due to the connection to a cooling tower system. Evaluating overall chiller plant performance will therefore involve an analysis of total power consumption of the compressor, pumps, cooling tower fans, etc. to evaluate comprehensive efficiency measures such as kW/ton.

Optimization of the overall chiller plant must be performed holistically. Various adjustments focusing on optimal chilled water setpoints, chiller sequencing, and load balancing, peak demand management, cooling tower water management, etc. can only be performed with operational data. IoT can provide the tools for such optimization by providing real-time monitoring of power consumption from each part of the chiller plant, supply/return temperatures from the chiller and cooling tower, water flow rates from the condenser water loop, etc. IoT has found practical application in HVAC to facilitate true optimization.

Conclusion:

Chiller operational efficiency will greatly impact your building operating costs. Ongoing routine maintenance represents the minimum from the perspective of facility management. Predictive maintenance and optimization of the chiller system require real-time operational data. IoT has opened the door to new forms of chiller efficiencies.